Grading by visual means is simply a sorting process based on the size and number of features present in the boards. Boards with fewer and smaller features are sorted into one grade while those with more frequent and larger features would be sorted into another grade. Each grade has specific criteria and is given a name which may be in line with one of three grades contained in Australian Standard AS 2796 – Timber – Hardwood – Sawn and milled products or a manufacturer grade where different grading rules developed by that manufacturer have been used in grading the flooring.

The purpose of this information sheet is to outline what the AS2796 grading standard for hardwood flooring covers, explain the different types of feature that may be present in each of the AS2796 grades, explain manufacturer grades that differ from the AS 2796 grades and provide guidance on ATFA manufacturer grade names and their alignment to AS 2796 grades.

AS 2796 – Timber – Hardwood – Sawn and milled products

The grading of solid hardwood flooring revolves around Australian Standard AS 2796 – Timber – Hardwood – Sawn and milled products. Grading rules have two specific purposes. The first is to address aspects of strength and serviceability when flooring is to be laid in structural applications such as over joists. The second aspect is to determine the character (overall appearance) present in a floor through the sorting of boards depending on the features present.

AS 2796 provides for three grades and the only difference between them is the size and number of the features permitted. In all other respects, that is moisture content, tolerances and machining imperfections there is no difference between the AS 2796 grades. It is important to note that the standard does allow manufacturers to produce their own grade and still comply with the moisture content and machining requirements in Part 1 of the standard. The standard does require that such manufacturer grades be documented and the onus is on the manufacturer to ensure adequate structural capability of the product in applications such as flooring on joists.

Concerning the grading rules, the appearance of the exposed surfaces of boards is graded differently to the un-exposed surfaces of the boards. It is also important to note that colour and board length are not covered by the standard.

The grading process is rapid and generally relies on quick visual assessment where graders must assess the size and extent of a feature without relying on measurement. Due to this some inaccuracy in grading can occur that may result in a limited number of boards that are outside grade limits. The sanding of a floor can also increase the size of some features or cause features to appear that were not present prior to sanding. Consequently, some boards in a finished floor may not meet the specified grade description. When viewing a floor there is generally a clear difference between a floor that is of the incorrect grade and a floor where grade limits have been exceeded in some boards. In some plants the grading process is now done automatically through scanners connected to computer systems which can make the grading process more precise. Grading may be to the AS 2796 grade description or to the manufacturers own grade.

Grading does not cover where boards will be laid in the floor. As such it is a reasonable expectation that the installer, when laying the floor, will provide a relatively even distribution of colour and feature throughout the floor. Similarly it can be expected that board lengths will be relatively evenly distributed in the floor and that groups of short boards or board ends will not be frequently clustered together. To some degree board length will influence this.

Grades and grade features in AS 2796

The intent of the grading rules is that through the grading of individual boards an overall character to the floor will be achieved. This may be summarised as follows:-

AS 2796 Grades

Select Grade – providing a floor where the feature present or natural discolouration will not dominate the appearance of the floor. Features that are permitted still include short narrow gum veins, a limited number and size of past borer activity and small knots.

Medium Feature – Standard Grade – providing a floor that may have significantly more character than a Select Grade floor. To some degree this will depend on the features present in a particular species. In one species gum veins may naturally be prevalent while in another there may be few gum veins but past borer activity may be more prevalent. Therefore, this grade can be expected to have greater character than Select Grade, and contain an increased amount of gum vein, past borer activity, knots and natural discolouration.

High Feature Grade – providing for a floor that contains boards with similar features to Medium Feature – Standard Grade but where the length of features such as gum veins may be longer and past borer activity may be more frequent. Again depending on the species, features will vary and in some instances boards meeting high feature grade may only appear moderately featured.

It should be note that the difference in appearance between a Select Grade floor and a Medium Feature – Standard Grade can be quite significant whereas the difference in appearance between a Medium Feature – Standard Grade floor and a High Feature Grade floor can be quite small.

AS 2796 Grade features

There are some natural features that are not permitted in flooring where their inclusion is known to affect the structural integrity of the boards. This includes fractures and splits through the board, enclosed termite galleries and decayed wood. Similarly, for appearance reasons there can be no obvious timber missing from exposed surface of floorboards. In other instances some features such as knots need to be limited in size also for structural reasons.

Provided below are some common features permitted in the grades:-

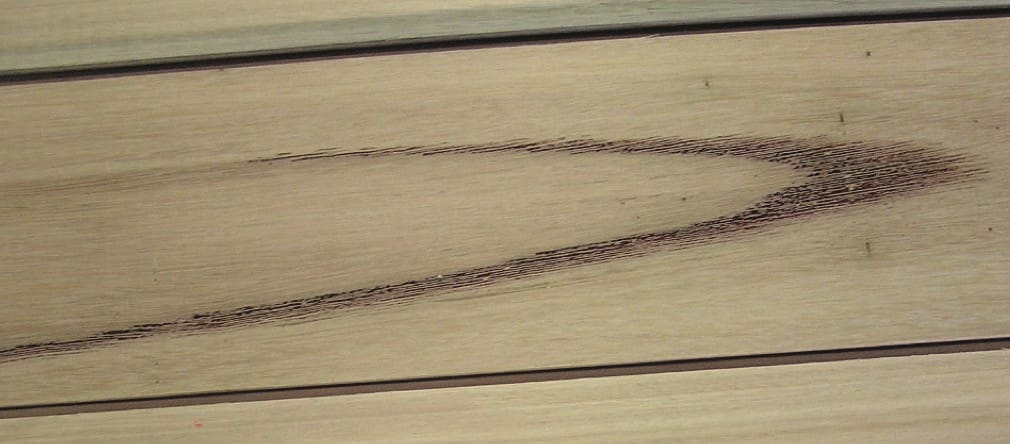

Gum veins

Tight gum veins are permitted in all three grades. The gum vein shown in the first photo being narrow and short in length is about the extent that is permitted in Select Grade. The second photo shows a backsawn gum vein that would be permitted in Medium Feature – Standard Grade. Due to the length of the gum vein in the third photo, this board would meet High Feature Grade requirements. In both Medium Feature – Standard Grade and High Feature Grade, loose gum veins (as opposed to tight) are also permitted to a degree. This is where there a lack of bridging fibres through the gum vein causes some separation.

Past borer activity can appear as a series of small holes in the board, as a trace going across the board and in some species as a zigzag pattern (known as hobnail). At times there is some discolouration associated with the borer mark. Less discolouration and fewer holes are permitted in Select Grade than the other two grades. The boards in the first and third of these photos would however meet Select Grade requirements. In the second photo the number of holes exceeds Select Grade limits but would meet Medium Feature – Standard Grade requirements.

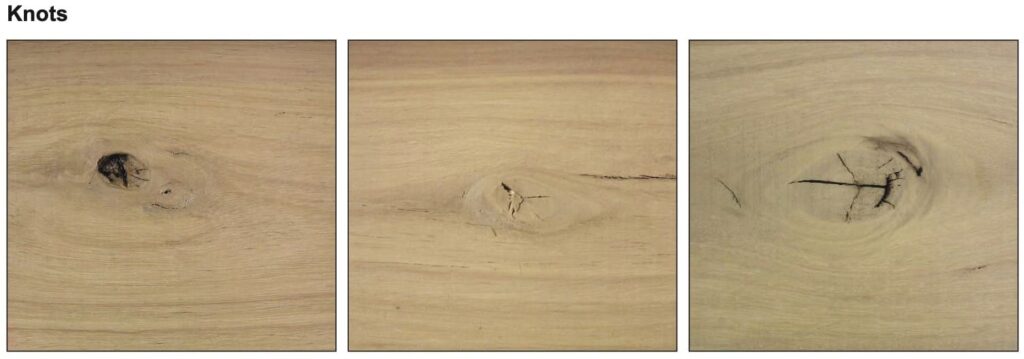

Knots and any voids (that is hollows associated with them) are permitted within limits in all three grades. The knots must be sound (will not fall out), however in Select Grade the splits that can be seen within these knots, known as knot checks, are not permitted. For this reason even though the size of the small knot in the first photo may be within Select Grade limits, the knot check would cause it not to meet grade. Due to this, even small knots are often not found in Select Grade boards. Knot checks are permitted in both Medium Feature – Standard Grade and High Feature Grade. The knot in the second photo meets Medium Feature – Standard Grade requirements and the knot in the third photo meets High Feature Grade.

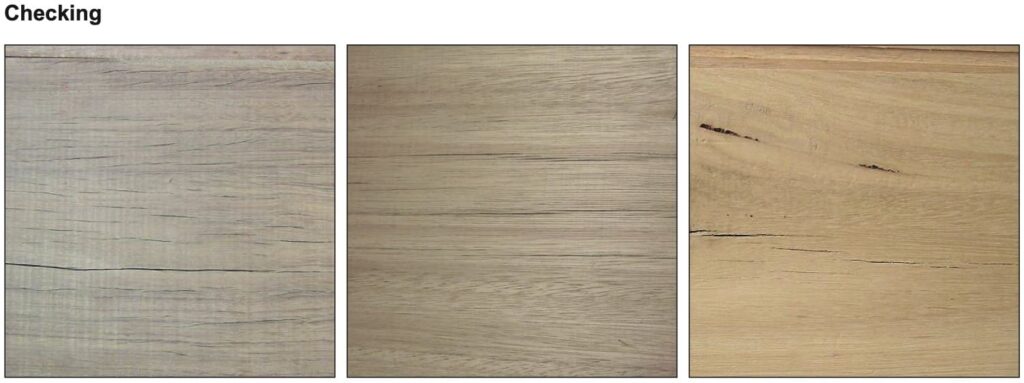

Checks are a separation of the wood fibre and differ from a split in that they do not travel from one surface of a board to another. They can often occur with rapid drying and be over much of the board surface. However, grain deviation with some boards or around knots as present in the third photo can also occur. Checking is permitted in all three grades and although multiple checks may appear on the board surface as in the first photo, they are considered individually by the grading rules. In Select Grade only short narrow width checks are permitted. In Medium Feature – Standard Grade there is the same length consideration as Select Grade but the check can be wider. In High Feature Grade the check can only be as wide as Medium Feature – Standard Grade but can be of any length. Unless the check in the first photo was about twice the length shown, then the checking in these photoswould meet Select Grade requirements.

When trees get damaged they have a great ability to protect and repair themselves, filling voids with gum and growing over the injury. Such features are not permitted in Select Grade but are permitted to some degree in both Medium Feature – Standard Grade and High Feature Grade. Due to the depth of the pockets in the first two photos they would not be permitted in any grade however in the third photo overgrowth, similar to this, could be present in both Medium Feature – Standard Grade and High Feature Grade.

The appearance in a floor

The features outlined above are those that have most influence of the character of the floor. The photos show individual boards but it is also important to understand how this may translate into the look of the floor. Provided below are two photos of Blackbutt floors. The first shows a Medium Feature – Standard Grade floor and the second a Select Grade floor. However note that depending on the logs and species being cut, all floors are going to differ in character and appearance. What should however be taken from this is that for a particular species, the level of feature in a Select Grade floor is going to be less dominant. To the bottom right of the photo of the Select Grade floor there is a board with a wider gum vein that would not meet Select Grade limits, however, even though this may have come about by the grader missing it or from sanding, its presence is not considered to detract from the overall appearance of the floor and is considered quite acceptable.

Manufacturer and AS2796 grading rules

In order to provide better use of our timber resources and account for the limitations there are with applying a common set of grading rules across a range of species, many manufacturers have developed their own set of grading rules with most manufacturer rules also complying with the moisture content and machining tolerances of AS 2796. In some instances the manufacturer has only undertaken small changes to the grade descriptions but in other instances they have responded to the market to provide grades that may lie for example between Select Grade and Medium Feature – Standard Grade. As a result of this there are many grade names present in the marketplace which at times can seem confusing. It must also be considered that not all grades are available in all species or species mixes. In addition to manufacturer grades there are also specific industry grading rules used by some.

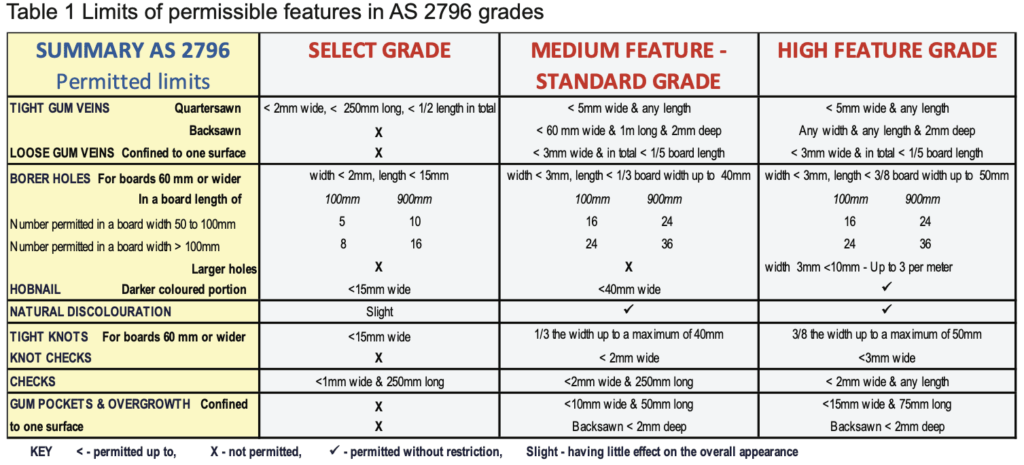

Provided below in Table 1 is a summary of the AS 2796 grading rules that influence the character of the floor. It must be understood that this does not cover other important aspects in AS2796 including how these features are to be measured. Therefore, if further assessment is required, a copy of the standard should be obtained or ATFA inspectors may be engaged to assist with an onsite assessment. Table 2 lists the ATFA solid timber flooring manufacturers, the grade names that they use, the level of feature associated with these grades and an indication of how their grades align with AS 2796 grades or where other grades have been introduced. Table 1 Grade limits of features that influence floor character. Summary based on AS 2796.

Table 2.1 ATFA Member T&G Hardwood Flooring Grades

| ATFA Member Grades for T&G flooring | |||||

| ATFA Manufacturer | Lightly Featured | Mix of Lightly & Moderately Featured | Moderately Featured | Mix of Moderately & Highly Featured | Highly Featured |

| AS2796 grading rules | Select Grade | Medium Feature – Standard Grade | a- | ||

| Australian Sustainable Hardwoods | Select | – | Standard | – | – |

| Blue Ridge Hardwoods | Select | – | Standard | – | Natural Feature |

| Embelton | Select | – | Natural | – | – |

| Howard Sawmill | Select | – | – | – | Feature |

| Hurford Hardwood | Select | – | Standard | – | Feature |

| Marshall Notaras Hardwoods | Select | – | Standard | – | Pioneer |

| Morgan Timber | Select | – | Standard | – | High Feature |

| Oakdale Industries | Select | – | Standard | – | Feature |

| Parkside Group | Select | – | Standard | – | Feature |

| Manufacturer grading rules | |||||

| Blue Ridge Hardwoods | – | Standard & Better | – | – | – |

| Pentarch Forestry | – | Standard & Better | – | – | Natural |

| Dale & Meyer | Premium | – | Character | – | – |

| Embelton | – | Select/Standard | – | – | – |

| Howard Sawmill | – | Standard & Better | – | Standard Feature | – |

| Hurford Hardwood | – | Prestige | – | Rustic | – |

| Coffs Harbour Hardwoods | Slight | – | Moderate | – | Heavy |

| ATFA Member Grades for parquetry | ||||

| ATFA Manufacturer | Lightly Featured | Mix of Lightly & Moderately Featured | Moderately Featured | Highly Featured |

| AS2796 grading rules | AS 2796 Parquetry Clear | AS 2796 Select Grade | AS 2796 Medium Feature – Standard Grade | AS 2796 High Feature Grade |

| Pentarch Forestry | – | Classic | Natural | – |

| Embelton | – | Select | Natural | High Feature |

| Marshall Notaras Hardwoods | – | Select | – | Feature |

| Oakdale Industries | – | Select | – | Feature |

Grade name mixes

One term that is commonly used is ‘Standard and Better’. This is a mix of Select and Standard grade flooring, however the percentage of each grade in the mix is not set and will vary between manufacturers and between one species and another. The intent is however to provide a floor appearance that has a little more character than Select Grade. Some manufacturers may supply such a grade while at times an installer may mix grades at the time of installation to suit an owner’s request.

In Western Australia the term ‘Standard and Better’ is often used to describe the appearance grade of local timbers such as Jarrah, Blackbutt and Marri where the mix could be expected to contain about 70% Select grade and 30% Standard grade. Another appearance grade commonly used in Western Australia is ‘Feature and Better’ which normally combines a mix of 50% ‘High Feature’ and 50% ‘Standard and Better’ to produce a specific visual impact. Note that this flooring still complies with the moisture content and machining requirements of the Australian standard but as grade mixes not to a specific grade description contained within the Australian standard.

Other grade names

In the market there are some grade names or grading terms where some care is necessary.

‘Cover Grade’ ‘Utility Grade’ or ‘Fall down’ are names often given to material that does not meet the grading requirements of AS 2796. They were names given when it was common in the past to lay a timber floor and have it ‘covered’ with carpet or other floor covering. Note also that the structural integrity associated with the AS 2796 grades does not necessarily apply when this terminology is used. Although such material could look to have few features, aspects relating to moisture content or board tolerances may not be in compliance with the standard.

‘Run of Mill’ is a term used to include the natural mix of grades that comes from the production and where no further grading except aspects relating to utility and structural soundness have been considered.

With each of the above or similar terms it is necessary to be particularly cautious due to the loose nature in which these terms are used and that they are open to interpretation.

European an American Oak Grades

Solid Oak flooring manufactured in Europe and America and also from China is often imported into Australia. As such the flooring is not graded to the rules outlined in AS 2796 and it is important to understand some of the differences. It should also be noted that European grading rules differ to American, and that both differ in concept when compared to Australia.

Before considering grade descriptions, there are two particularly important aspects to consider when this flooring is being imported. The first is moisture content. In the USA, both the National Wood Flooring Association and Northern Oak Flooring Manufacturers Association indicate that Oak flooring is manufactured with 95% of pieces in the moisture content range 6% to 10%. So this is quite different to the 9% to 14% range in AS 2796, and therefore Oak flooring can experience severe in-service expansion effects if laid at its low manufactured moisture content in more humid environments. But also note that acclimatisation of low moisture content flooring, and particularly with wider boards, can result in significant cover width variation and laying difficulties.

The second aspect is Oak’s susceptibility to the Lyctus borer attack. This insect can attack the sapwood in Oak flooring, if it has not been treated.

The Australian standard AS 2796 sets out the requirements for flooring manufactured in Australia. Therefore, it can be expected in terms of moisture content, that Oak (and other imported species) would be supplied within a 9% to 14% moisture content range (unless by agreement between purchaser and seller as also provided for in AS 2796). Also, since Australian manufactured flooring is to meet AS 2796 and not contain Lyctus susceptible sapwood, then nor should it be seen as permitted in imported Oak or other species.

When considering the grade descriptions two examples will be provided that are more often seen in Australia, but again it also needs to be considered that other grading rules also occur.

The first grading system to be considered from Europe, is based on the size and frequency of features and uses the designated letters A to F, and flooring may be supplied to ABCD grade. So we need to consider what these letters mean. The letter A refers to boards that are uniform in grain and colour while F represents boards that are very heavily featured. Hence AB grade boards will have a very clean looking appearance without knots and minimal colour variation and the term ‘Prime’ may at times be applied to it. More often we see ABCD grade and this would represent boards with colour variation including sapwood and some features including knots. Note also, that growing region and climate have an effect on appearance and white oak from North America and Russia generally has more regular grain and less colour variation than European Oak which is also often darker in colour.

For Oak from the USA, a grade that may be imported is FAS or perhaps No. 1C. The first of these terms FAS stands for ‘Firsts and Seconds’ and in this grade about 80% of the board length will be free of feature and is referred to as a ‘cuttings grade’. That is, features can be cut out to provide clear timber for cabinet work etc. The term ‘Selects’ refers to ‘Selects and Better’ or ‘Prime’ may also be used, which are variation on FAS to provided boards with the desired appearance. We also mentioned No. 1C and this stands for ‘No. 1 Common’ and with this, a clear yield of about 60% clear wood is achievable. With this grading system there are some features that are permitted and others that are not. Additionally, although sapwood is included in the above grades, boards may also be sorted, where sapwood free boards would command a higher price.

Therefore, it can be seen that grading of imported Oak varies significantly from the way flooring is graded in Australia, and care is also required not only with this, but also regarding moisture content and the possible presence of Lyctus susceptible sapwood.

Recycled hardwood flooring

The grades applicable to recycled hardwood flooring may be specified in line with the AS 2796 grade descriptions or where greater character from bolt and nail holes etc is desired than separate grading rules apply. The grading rules for recycled hardwood are contained in ‘Interim Industry Standard Recycled Timber – Visually Graded Recycled Decorative Products’ from Forest and Wood Products Australia.