Timber is a natural product that is hydroscopic, which means that it responds to changes in weather conditions by absorbing moisture from the air under high humidity conditions and conversely releasing moisture back into the air under dry or low humidity conditions. With the changing seasons, this occurs in a cyclical manner. The resulting change in board moisture content causes solid timber floorboards to shrink and swell in their width. Engineered flooring and laminate flooring will also expand and contract – in both width and length – however the degree of movement is significantly less than with solid timber flooring due to their constructions.

Although seasonal movement in timber-based flooring is quite small and not observable on a day-to-day basis, the movement over a few months can be quite significant and needs to be accommodated for during the installation process by adding expansion allowance and movement control joints. Heating and cooling systems, affecting both the internal temperature and humidity, will also bring about changes to the internal dwelling climate and generally have the effect of moderating internal conditions, if not used excessively.

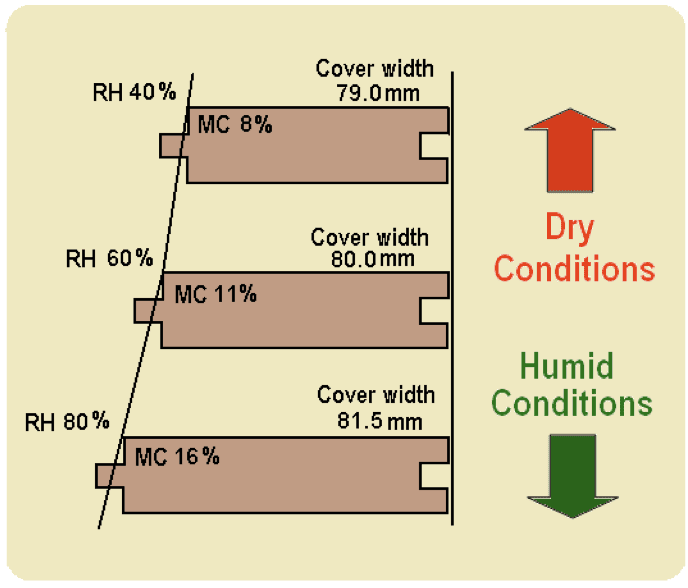

As such, timber flooring products will adjust their moisture content to be in equilibrium with the humidity and temperature conditions within a building, prevailing at the time. Solid timber flooring is said to adjust towards the Equilibrium Moisture Content (EMC’s) range of the environment inside the house or building. The adjacent diagram, for solid timber flooring, shows the general relationship between moisture content, relative humidity (RH) and board width. At 25ºC and 60% RH the EMC is 11% and at 25 ºC and 80% RH the EMC is 16%. If the moisture content of solid timber floorboards at the time of installation is higher or lower than the in-service EMC, then the floorboards will either release or absorb moisture to approach the EMC and when this occurs there will be either shrinkage or swelling after installation, as also indicated in the diagram by a change in board width.

With solid timber flooring, acclimatisation is simply a process of getting the moisture content of the flooring closer to its expected in-service average moisture content, so that shrinkage or swelling of the floorboards will be less after installation. Although engineered and laminate flooring also undergo similar seasonal movement, the word acclimatisation generally has a different meaning to that used with solid timber flooring and the practices used with solid timber flooring do not apply. Acclimatisation as referred to by engineered and laminate manufacturers is discussed later in this information sheet.

Changing practices and techniques with solid timber flooring

Before the introduction of engineered and laminate flooring, both the understanding of solid timber drying processes and the techniques available, were not as advanced as they are today. In some instances, flooring was also supplied only partly seasoned. Often with feature floors there was an expectation that the floorboards would be cut in upside down and used as a work platform over joists, and that during that time before turning over and fixing, the flooring would acclimatise. Flooring that was supplied as seasoned, also often had a range of moisture contents between boards that was greater than would be acceptable today. Acclimatisation was nearly always recommended, although many suppliers and installers did not really understand all aspects of the process; it was just something that they had to do. Suppliers could claim in those instances where the floor did not meet expectations, that the floorboards were not properly acclimatised. As such, the expectations of yesteryear were not as exacting as those of today. With improved drying practices and quality control procedures, floorboards can now be supplied at a moisture content that is more predictable and within tighter limits. The Australian manufacturing standard for solid hardwood flooring (AS 2796) indicates an acceptable drying range of 9% to 14%. Within this range, solid timber flooring is normally supplied at an average moisture content between 10% and 11% from most major Australian manufacturers. This average moisture content suits many of the major city dwelling environments from Melbourne to Brisbane, and also the likes of Perth. At an average moisture content of 10% to 11%, the post installation movement in solid timber floors will generally be small and there will be no need to acclimatise the flooring prior to laying. Seasonal movement being accommodated by the usual expansion allowance provided during installation. So, the flooring is manufactured to a more precise moisture content range suited to average internal humidities of 50% to 60%, that often occur.

In high humidity locations such as north Queensland where floors are exposed to relative humidities of 65% to 80%, or higher during cyclone periods, an average floorboard moisture content prior to installation toward the mid-to-upper end of the manufacturing range can be achieved through acclimatisation. As such, the purpose of acclimatisation in this instance is to raise board moisture content and pre-expand the floorboards prior to laying, and then the usual expansion allowance provided will accommodate the seasonal variations. If in such environments, the flooring is installed during the drier time of the year, acclimatisation will not be sufficiently effective and additional expansion allowance would need to be provided at installation.

In dry inland locations the average relative humidity within a dwelling may range from 30% to 50%, and conversely, through acclimatisation the flooring can be pre-shrunk prior to laying to minimise gapping after installation. The usual expansion allowance is then provided to accommodate seasonal variations.

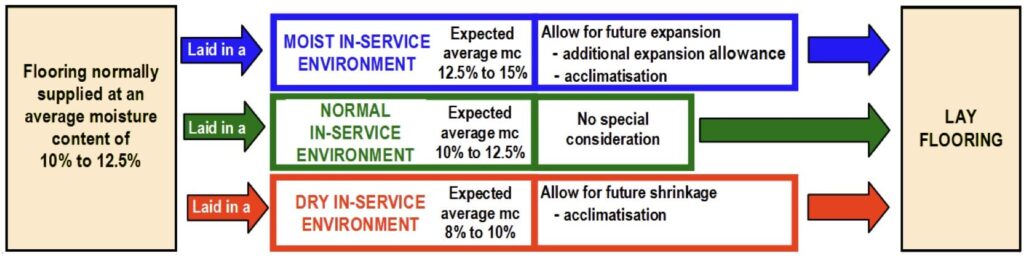

The diagram below summarises the above concepts.

Acclimatisation will not correct poor solid timber flooring drying practices

Poor drying practices result in a wide moisture content distribution in the boards supplied. That is, flooring not supplied in a tight 9% to 13% moisture content range, but in a range from say 9% to 18%. Boards insufficiently dried will have been produced with a uniform cover width at manufacture, but as indicated a significant variation in board moisture contents. Therefore, with acclimatisation, the moisture content range will be reduced but the cover width variation will increase significantly. That is, the higher moisture content boards shrink but the lower moisture content boards don’t. Because of the increased variation in cover width, the flooring becomes impractical to lay. If not acclimatised, the boards of high moisture content will shrink after installation and the result will be a floor that develops narrow to wide gaps at board edges. It follows that poorly dried floorboards are not conducive to an attractive feature floor, irrespective of whether the flooring has been acclimatised or not.

Solid timber flooring installation moisture content and acclimatisation

Acclimatisation of floorboards prior to installation is not necessary when the average supplied moisture content of the flooring is near the expected average in-service moisture content. Unnecessary acclimatisation can cause problems, especially if the floorboards are acclimatised to a building site environment that is somewhat different to the expected in-service environment.

Successful acclimatisation of solid timber flooring relies on a number of factors

- Determining the expected in-service EMCs within the dwelling.

- Ensuring acclimatisation is to the desired in-service moisture content rather than to the EMC of the building site environment.

- Estimating the moisture content of the flooring prior to installation. This requires the proper use of resistance moisture meters as outlined in ATFA Information Sheet 8 – Resistance Moisture Meters. Species corrections for common flooring species are contained in that information sheet and correction figures for other species may be found in AS 1080.1.

- Determining how wide the expected in-service EMC variation is throughout the year.

- Assessing the moisture content change required (e.g. supplied at 10% and expected to average 13% when in-service).

- Evaluating the time necessary for adequate acclimatisation. The time depends on the moisture content change required and the response time of the particular species. Some species have a fairly quick response time while some have quite a slow response time.

- Understanding that acclimatising wide boards can result in board ends flaring or narrowing as moisture movement is faster through board ends. As such this needs consideration.

The expected in-service environment is influenced by a number of factors, including:

Heating, which has the effect of lowering the EMC in the house. In cool temperate climates this can create quite a dry internal environment. The environment in the upper level of a heated two-storey house is often drier than the lower storey.

Refrigerated air-conditioning if used continuously can dramatically reduce the general moisture content within the house.

Shutting a house up when away on holidays for long periods can create abnormal humidity conditions and therefore some ventilation may need to be considered depending on the time of the year.

Full length windows, large glass areas and skylights which admit direct sunlight can create sunroom conditions with high temperatures and low moisture conditions, causing flooring to shrink.

Proximity to bodies of water such as the ocean, a river, lake, dam or wetlands.

Prevailing winds that are either moist or dry.

Climatic variation throughout the seasons. Data is available for Australia at www.bom.gov.au and in New Zealand https://niwa.co.nz/.

- Local environment e.g. leafy gully, rural residential areas or generally treeless area.

If the environment inside a lived-in house has an EMC variation from summer to winter of no more than about 2%, there is not likely to be a very noticeable difference in the floor as it adjusts to the seasonally changing EMC. However, if the building environment has a seasonal EMC variation of 3% or higher, there is likely to be noticeable movement. A general rule of thumb is that for every 3% change in moisture content, the dimensional change in the width of a solid timber floorboard will be about 1%. Therefore a 3% change in moisture content will cause a board with a cover width of 80mm to change in width about 0.8mm. For a 180mm wide board this would be about 1.8mm. Note that this is more apparent with floorboard shrinkage.